LUXEWALL2.3 is a new high-performance aluminium sheet with a continuously applied liquid paint coating that is particularly suitable for modern architectural facades.

LUXEWALL 2.3: caracteristic

- perfect flatness;

- in Aluminium-Magnesium alloy, series 5000;

- extra-thick solid metal (2 to 3 mm thickness);

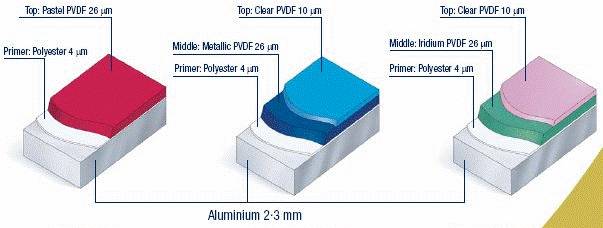

- PVDF coating applied in 2, 3 or 4 coats;

- available in innovative finishes: pastel, metallic, iridescent and personalized;

- ersonalized packaging, so that the rolled section is immediately identifiable and provided with the utmost

- protection during transit and handling;

- thorough, strict, certified quality controls throughout the production cycle;

- very thick protective film;

- delivery time: extra fast. Thanks to fast-track production planning and to the just-in-time production and delivery service.

TECHNICALL DATA SHEET LUXEWALL 2.3

Basic alloys: serie 5000 (chemical composition uni en 573-3 1996 norm)

Physical estate: H42/H44/H111 (in accordance with UNI EN 485-2 norm)

Thickness: between 2 and 3 mm

Width: up to 1550 mm

Length: coils or sheets up to 6,000 mm

Coating: PVDF paints

Finishes: standard (pastel), metallic, iridescent and personalized

Colours: main colours of RAL folder and personalized finish on demand

Protective film: protection in LDPE, UV-resistant

Weather resistance: maximum

Fire reaction: low flame spread (RWTUV certification, class A1*)

Workability: very thick coating resistant to bending and deformation, no cracking at a minimum of 2T

Impact resistance: no cracking at a maximum of 10 Nm

Off-cuts recycling: 100% recycle

Flatness: total “Panel Quality" (continuous stretching), in accordance with the EN 485-4 norm

Appearance: completely evenness of finish and colour

| Type of product | Side | Type of resin | Film basisi weight | Film thickness |

Gloss | |

| Partial | Total | |||||

| LUXEWALL2.3 PVDF metallic/ iridium | External | –Primer polyester | ≈5 g/m2 | ≈4 µm | ||

| -PVDF (Kynar 500 70%) Metallic/iridium |

≈30 g/m2 | ≈26 mm |

||||

| -Top (Kynar 500 70%) Clear | ≈10 µm | ≈40 µm | max 35° | |||

| Internal | Back coating Polyester or Epoxy |

≈5 g/m2 | ≈4 µm | |||

| LUXEWALL2.3 pastel PVDF | External | –Primer polyester | ≈5 g/m2 | ≈4 µm | ||

| -PVDF (Kynar 500 70%) Architectural colours | ≈30 g/m2 | ≈26 mm |

≈30 µm | max 35° | ||

| Internal | Back coating Polyester or Epoxy | ≈5 g/m2 | ≈4µm | 60° | ||

CARACTERISTIC |

LUXEWALL 2.3 |

FIRE REACTION |

A1 class material non-combustible. |

| INTERNATIONAL COMPLIANCE |

It may be used in all states and building types. |

MECHANICAL WORKING |

Scoring: unnecessary. |

| INTRINSIC VALUE OF PRODUCT/ RECYCLING | At the moment of elimination all scrap can be reused. |

| In the long term it is cheaper | |

| GUARANTEE | Coverage required only for aluminium and paint (PVDF Kinar 500 with 30 year guarantee) |

| IMPACT TEST | strong resistance that prevents the surface of the material to suffering damages. |

| DRILLING PENETRATION |

Good resistance. (deepening 7) |

| COLOUR RANGE |

“Unlimited": more than 2000 colours (deepening 8) |

| ALLOY USED |

LUXEWALL is made using exclusively 5000 aluminium magnesium alloy (deepening 9) |

| WIND PRESSURE | high inertia module (J = 0,225 cm4/m) |

SOUNDPROOFING(tests conducted in accordance with international standards ISO/DIS 717-1 and EN ISO 140-3) |

Thickness: 2.9 mmSoundproofing powerRw = 28 Db. (The solid aluminum ensures good sound insulation) |

| FLATNESS | total |

| PROTECTIVE FILM | Covered with protective film to protect panel against damage during handling and installation |

| MAINTENANCE | requires limited maintenance (hot water and neutral detergent) |

IN DEPTH ANALYSIS

- fire reaction

- international compliance

- mechanical workings

- recycling-purchase cost

- guarantee PVDF

- impact resistance

- drilling penetration

- colour range

- aluminium magnesium alloy

- FIRE REACTION

The best characteristic of solid aluminium is that there is no fire risk.

It is a product classified by the European legislation Class A1 fire reaction, in accordance with EN 13501-1 standards, that means it is a non-combustible material. Solid aluminium is absolutely incombustible, it doesn't generate toxic fumes.

- INTERNATIONAL COMPLIANCE

LUXEWALL 2.3 is A1 class material (non-combustible).

According to European standards (which may vary slightly from state to state as a result of incorporation into national legislation, but which will be harmonised in the foreseeable future), incombustible materials must be used in all buildings taller than 20 metres (or less, depending on whether fire escape staircases are installed) and in all public buildings, such as schools, hotels, hospitals etc., irrespective of height.

For example, for a school or hotel in Italy, which must be equipped with fire escape routes leading, in the majority of cases, to a fire escape staircase, the Ministerial Decree of August 19th 1996, concerning places of public entertainment (which, in the absence of specific legislation is also applicable to other public buildings, such as schools) states that “the outer wall of the building against which the staircase and relative fixtures are installed must meet fire resistance requisites of at least REI 60 for a width equal to the projection of the staircase plus 2.5 metres one each side". Clearly, any such wall built using inflammable external panels could never attain a rating of REI 60. Moreover, it is becoming increasingly difficult to obtain fire insurance for private buildings clad with inflammable materials.

- MECHANICAL WORKINGS

Forming panels from solid aluminium is much easier. Curvatures with radii of just a few millimetres can be achieved simply with a bending press, rendering the scoring usually needed for sharp bends unnecessary.

This means saving of time, costs and greater rigidity of the panel.

If sharp bending is expressly requested, the scoring of LUXEWALL 2.3 is very easy. Solid aluminum, on the bottom of the scored lines can be left up to 1,5 mm full metal and bend so the panels according to the 90° pattern, obtaining in this way a considerably resistant panel also in correspondence of the scored corners.

- RECYCLING PURCHASE COST

Solid aluminium is totally recyclable, which means it can be remelted and all the waste can be used again. This means that besides being eco-compatible, there is no cost in disposing of solid aluminium rather its value can be completely recovered.

This makes LUXEWALL 2.3 a long-lasting choice, like a bank, which gives you a return on your investment over time.

With an expected life of more than 30 years, any waste will still continue to be an important financial asset.

- GARANTEE PVDF PAINT

The LUXEWALL2.3 panels are feature an exclusive PVDF, high thickness coating, guaranteed for up to thirty years. All the paints used contain at least 70% fluorinated polymer resin.

These materials, when applied to appropriate substrates, result in coatings offering a number of significant advantages, including:

– outstanding colour stability

– durability and strong weather resistance

– proven resistance to chalking, abrasion and chemicals.

Pvdf coating: 20 to 40 years guarantee

- IMPACT TEST

The impact test measures impact resistance of an aluminium panel.

the Impact resistance is very high in solid aluminium, because the impacting part knocks against a 2/3 mm metal sheet, which exercises a higher resistance to the movement. Therefore the effect of a hailstorm on a facade coated with solid aluminum panels would be minimal.

- DRILLING PENETRATION

The 3 mm of solid aluminium make the material very resistant to drilling

- COLOURS RANGE

LUXEWALL2.3 is available in an almost unlimited range of colors, offering more than 2000 different finishes whose include iridescent, metallic, almost all Ral colors and endless possibilities.

The R & D lab is developing special anti-graffiti paint, scratch-resistant, self-cleaning, anti-static, self-reflective.

- ALUMINIUM ALLOY

The type of alloy used in the manufacture of a panel is fundamental for its quality and performance. The panels resistance to wind pressure and stress is proportional to the strength of the aluminium alloy used in its manufacture. LUXEWALL 2.3 use exclusively the Leagues More performance, namely the 5005 or 5754, depending on need different project requirements.